Microfeeding at its best

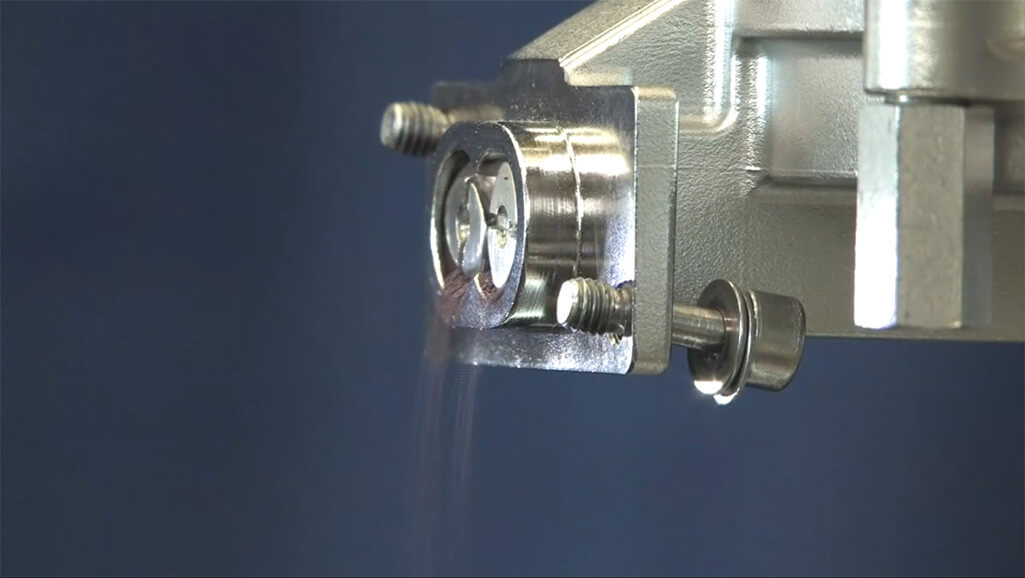

Coperion K-Tron’s family of twin screw microfeeders has been specially designed to provide maximum accuracy at minimal feed rates, which makes these feeders ideal for use in the chemical and pharmaceutical processing industries. Unique design features ensure that high value ingredients are fed accurately at rates as low as 32 g/h with minimal residual material left in the feeder. The modular design means more flexibility for the process and easy access to all parts for cleaning and maintenance. The 12 mm and 16 mm twin screw feeding modules are completely interchangeable and can feed a wide range of free-flowing to difficult powders.

Coperion

Open navigation

Coperion

Open navigation