Why Continuous Manufacturing for Battery Masses

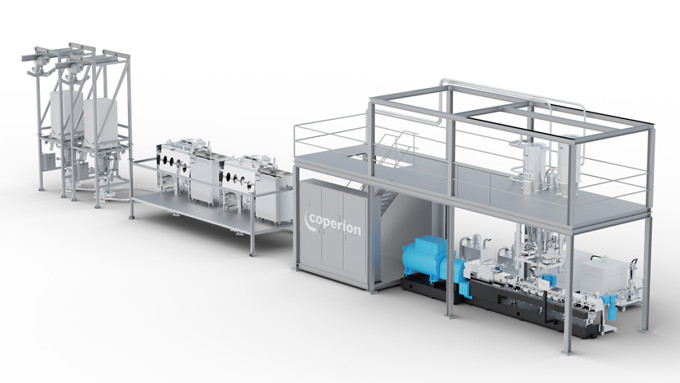

In the rapidly evolving battery industry, continuous manufacturing of electrode masses offers a transformative approach to battery production. At Coperion, our ZSK twin-screw extruders enable a highly efficient, cost-effective, and environmentally friendly process — delivering superior product quality as well as scalable throughput. Whether you operate in wet or dry processes, our systems offer flexibility, precision, and reliability from lab scale to full gigafactory production.

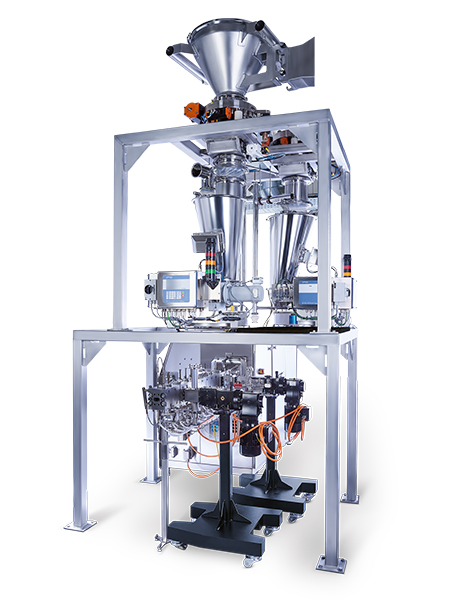

Coperion’s ZSK Mc18 or STS Mc11 twin screw extruder is the ideal extruder for meeting targeted requirements. It offers highly dispersive mixing capacity, breaking up solid agglomerates very effectively. Subsequent distributive mixing ensures the homogeneity required for high end product quality in battery masses.

The process sections of all Coperion extruders feature a modular design which allows our process engineers to tailor the configuration of the barrel and screw elements to your individual application. Additionally, the intermeshing twin screws of the extruder deliver consistently high conveying efficiency together with an optimal self-cleaning function within the process section, which minimizes residual material in the extruder and reduces waste.

Learn more about the ZSK Mc18 extruder and the STS Mc11 extruder.