Why accurate feeding is critical in battery production

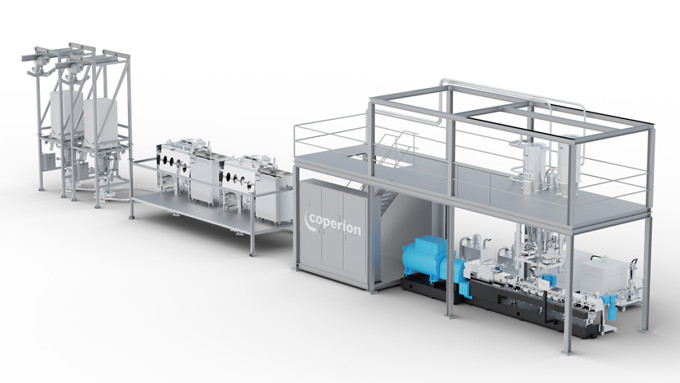

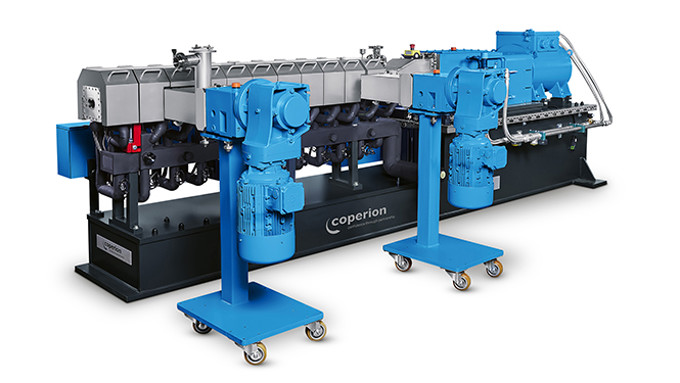

One vital aspect in battery manufacturing is the safe and reliable introduction of raw materials into the process. A variety of feeder technologies are available, depending upon the raw materials and process step. With comprehensive expertise and a wide variety of feeding solutions, Coperion has the right feeder for every application.

Our feeders excel with high accuracy and reliability. The interplay between mechanical construction, the latest weighing technology and advanced control is critical for achieving the highly accurate feeding performance. The “Smart Force Transducer” technology provides high-accuracy weighing, using weighing systems with a resolution of 1:8,000,000 in 20 ms. Precise control and process data on the bulk material allow manufacturers to profit not just from adherence to precise formulations, but also from less maintenance and downtime. A more stable process with reduced costs is the result.

Coperion

Open navigation

Coperion

Open navigation