Conventional Mechanical Recyclate Processing Requires Two Process Steps

Plastic waste contains impurities that must be eliminated through melt filtration, a process that subjects the waste plastic to mechanical and thermal stress. After filtration, the plastic is granulated.

The next step involves compounding with additives to imbue the plastic with the desired mechanical properties. This involves melting the plastic again and mixing it with additives such as glass fibers, fillers or color pigments, subjecting the plastic to a second round of mechanical and thermal stress.

This conventional approach to recycling plastics involves two separate steps and requires two processing machines, significantly increasing not only the complexity of the equipment but also the space requirements.

ZSK FilCo Filtration Compounder: Single-Step Processing

Coperion has engineered the ZSK FilCo filtration compounder to achieve the filtering and compounding of post-consumer recyclate (PCR) and other heavily contaminated polymers in a single production step.

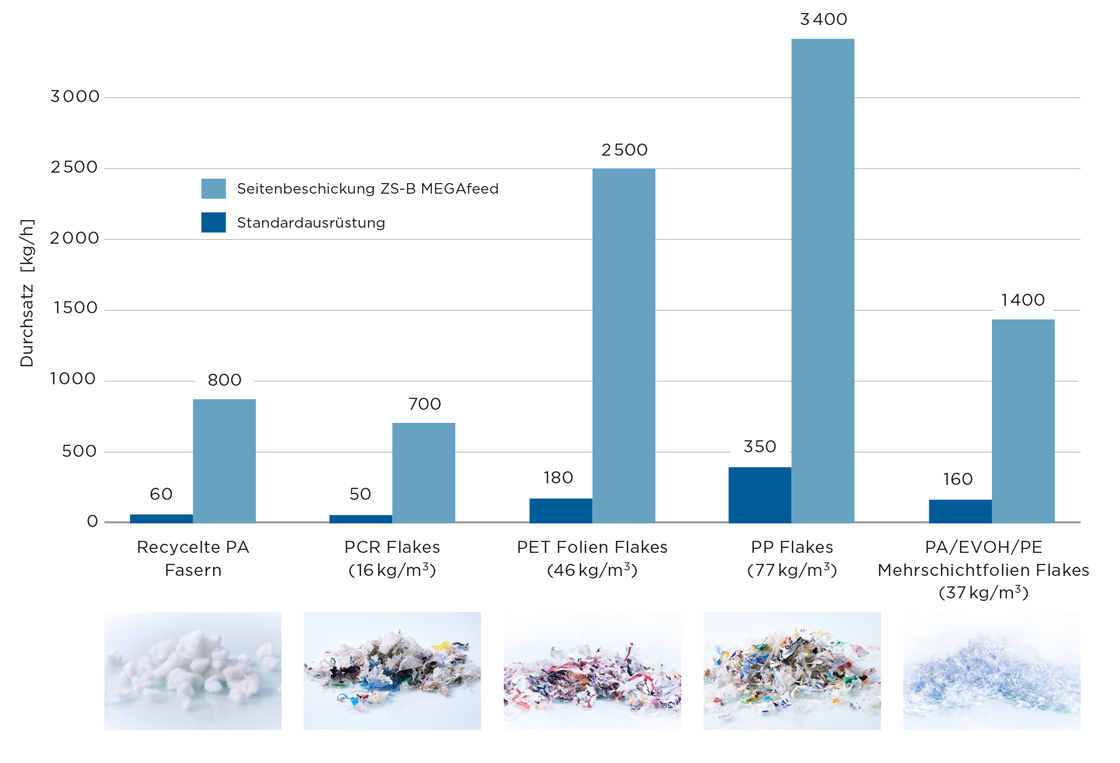

Waste plastic – in the form of regrind, fiber pellets, film flakes or agglomerate – is fed into a ZSK twin screw extruder where it is melted with all components (any polymers: PE, PP, PA, PS, PC/ABS, etc.), homogenized, and devolatilized. The melt is then discharged out of the ZSK extruder and an integrated filter removes all contaminants. The cleaned melt is reintroduced into the ZSK extruder, where reinforcing materials such as fiberglass, wood, and carbon fibers, or fillers such as talc, CaCo3 or ground PEX are added. The recompound is then pelletized.

This single-step recycling process using the Coperion ZSK FilCo is characterized by its extremely streamlined machine set-up. Filtration and compounding are possible in just one processing machine. This results in a more than 50% reduction in energy consumption for the extrusion process and significantly lower emissions in comparison to the two-step process.

The plastification process is very stressful for the plastic. The deformation and subsequent transition into the melt phase can mechanically and thermally stress the molecular chains, potentially causing them to break down. However, with the ZSK FilCo, the plastic is only subjected to this stress once, maintaining its chemical structure as much as possible. Consequently, the quality of recompounds produced using the ZSK FilCo is exceptionally high.