Hazardous materials are commonly used in various industrial processes – especially in the production of chemicals, plastics or batteries. Due to their toxic properties, both plants and research laboratories need to comply with strict safety standards to protect both workers and the environment. In addition to our test center for bulk material handling, Coperion offers a fully equipped research lab for hazardous materials such as ternary cathode materials (CAM) at our site in Niederbiegen, Germany. Learn more about our test capabilities in the following infographic:

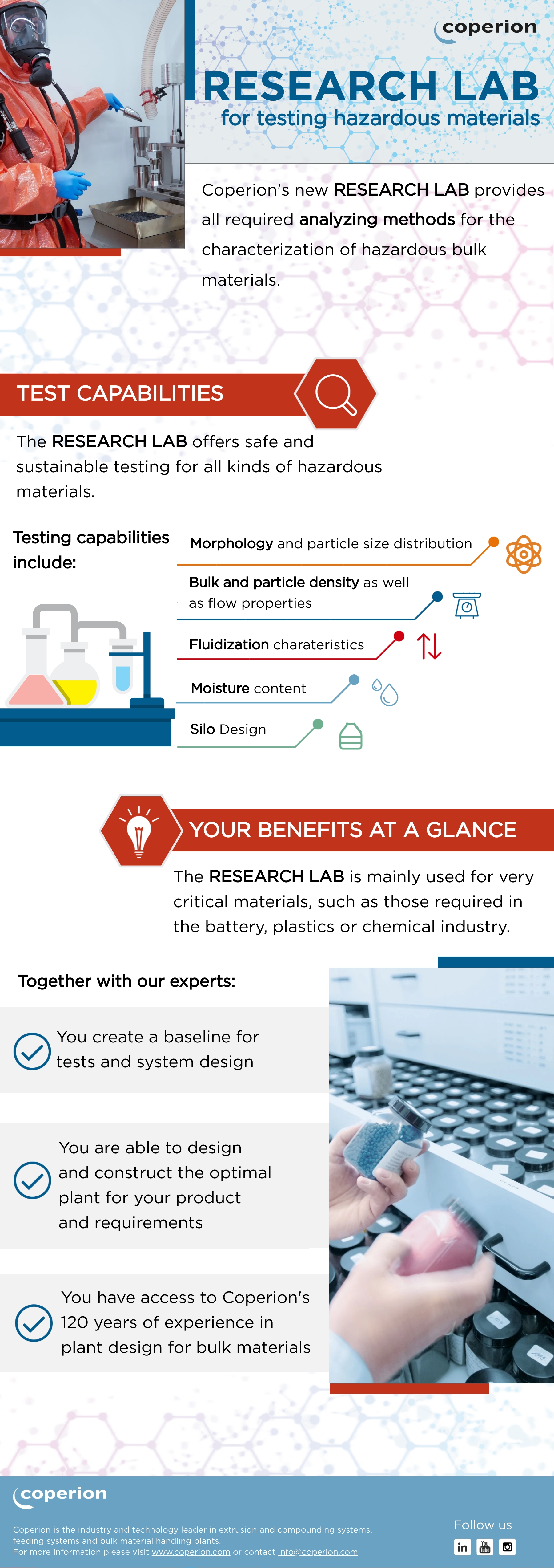

Before designing a plant and choosing equipment, manufacturers need to thoroughly investigate the materials that will be handled throughout the production process. Therefore, it is essential to conduct a variety of tests in the early stages of the project. Coperion’s research lab provides all required analyzing methods for the characterization of hazardous bulk materials. Our test capabilities include:

Morphology and particle size distribution

With our test equipment such as the laser diffraction particle size analyzer, we are able to analyze the size, shape and structure of the material. From this information, we can derive valuable insights and the size distribution.

Bulk and particle density as well as flow properties

Understanding flow properties of materials is crucial for choosing the right components such as rotary or diverter valves for the plant. Our experts are highly experienced when it comes to measuring bulk and particle density as well as flow properties.

Fluidization characteristics

When handling materials in an industrial context, fluidization characteristics are essential for the process and ultimately the plant design. This can be analyzed by fluidization test device.

Moisture content

Moisture content is another important parameter as it may have a considerable impact on the product quality. Our experts can give valuable recommendations in terms of the set-up or equipment based on the results of the tests.

Silo Design

In addition, it is possible to determine the flow properties by measuring the necessary bulk solids characteristics with the aid of shear tests. Herewith various silo options can be investigated, in order to find the right solution for the product at hand.

In summary, Coperion’s research lab for hazardous materials offers a number of advantages. Together with our experts, you will be able to create a baseline for further tests (e.g. in our test center for material handling) and the system design. This will put you and our team in the position to plan and construct the ideal plant for your products and requirements. Thanks to more than 120 years of experience with bulk materials and their behavior in various manufacturing processes we are confident to find the right solution for you.

Download the Infographic

Learn more about Coperion’s Capabilities

Test Centers for Material Handling

The Coperion and Coperion K-Tron test centers for material handling are some of the most advanced facilities in the world for studying bulk solids handling and processing.

Battery Materials

Coperion and Coperion K-Tron offer first-class, reliable technology for manufacturing top-quality battery compounds.

Individual Plant Concepts and Customized Systems

From manufacturing through to the end product - We provide individually tailored plants for the plastics industry as well as customized systems for all processes along the process chain in various industries.

Coperion

Open navigation

Coperion

Open navigation