Combination systems

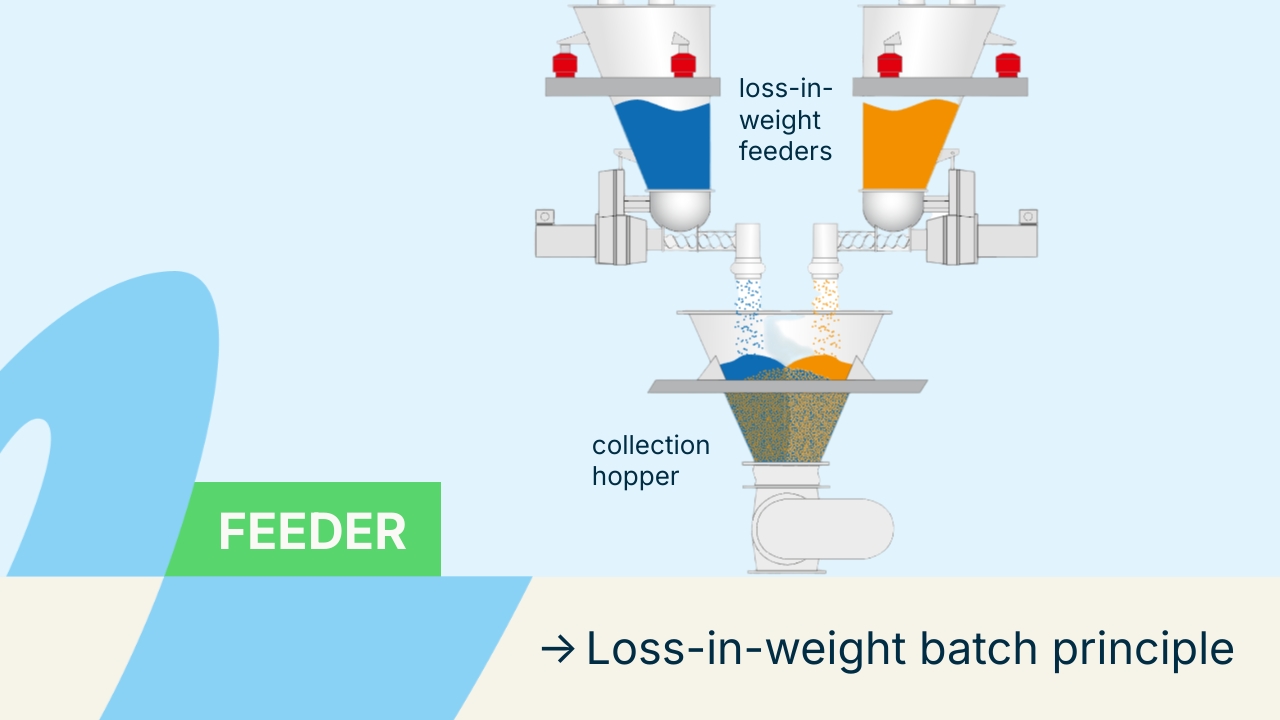

Many times, a combination of the GIW and LIW batching can be used to make the overall batching operation more cost-effective. GIW batching techniques are used for the macroingredients, and separate LIW feeders are used for the microingredients, whose batch weights may be too small to be detected by the GIW scale hoppers.

How do I choose?

Each of these technologies have inherent advantages and limitations. In order to choose the most efficient system, it is important to review the critical criteria required for the system as a function of batch time, accuracy required, amount of time allowed for quick changeover/cleaning and of course, overall cost.

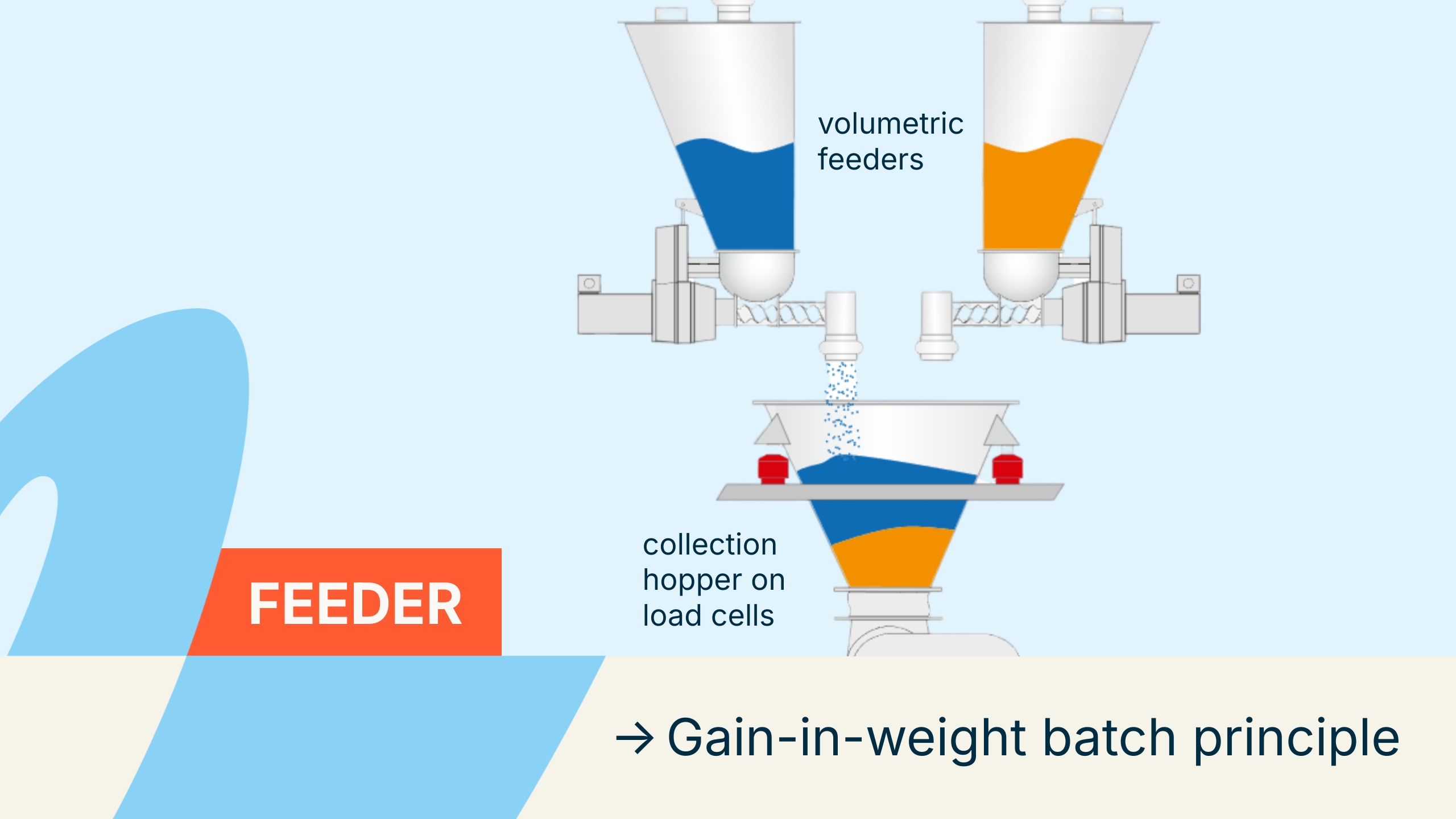

Optimization of batch accuracy will also be a function of the load cell resolution available. For example, in GIW batching, when discharging into a hopper or receiver on load cells, the accuracy is a function of the full scale load of receiving vessel plus product. In other words, a system designed to add both macro and micro ingredients in the same vessel may not be able to detect accurately the smaller amounts. Therefore, many times, in order to make the overall batching operation more cost effective, a combination of the GIW and LIW batching is used. GIW batching techniques are used for the macro ingredients, and separate LIW feeders are used for the micros whose batch weights may be too small to be detected by the GIW scale hoppers.

Once the correct type of batching technology is chosen, several other design options can be integrated into the system to make it more efficient. These include easy access and easy clean support devices and frames, quick disconnect systems, and even wash in place features in order to allow for quick product changeover and cleanability. It is important to discuss all of these options with the batching system manufacturer, in order to ensure the most efficient overall batching operation.

Coperion

Open navigation

Coperion

Open navigation