Trailblazing New Development for Plastic Fiber and Flake Recycling

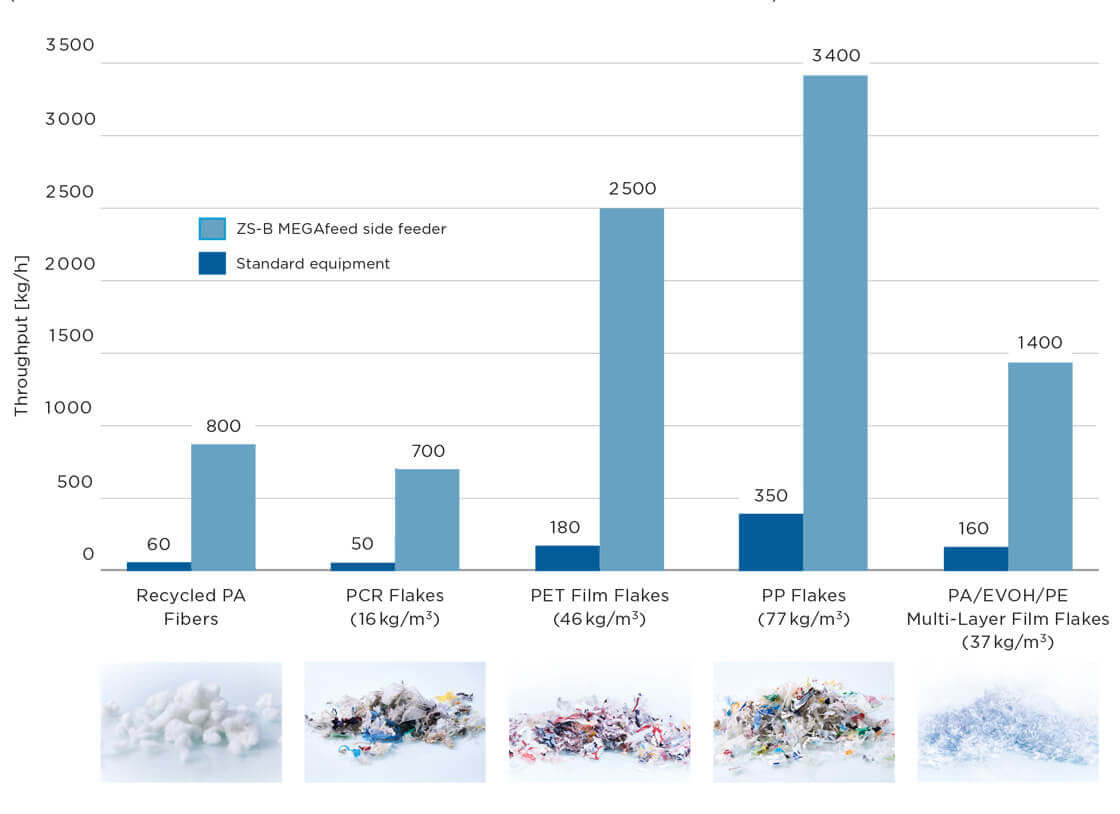

With the ZS-B MEGAfeed side feeder from Coperion, the recycling of plastics reaches a new dimension. The ZS-B MEGAfeed makes the recycling of lightweight, very voluminous recycled flakes and fibers significantly more economical and, in some cases, possible in the first place.

Thanks to the innovative design of the ZS-B MEGAfeed side feeder, plastic recyclate with bulk densities starting as low as 20 kg/m³, which was previously considered feed-limited and therefore not economically recyclable, can be reliably fed in large quantities into the ZSK twin screw extruder.

Coperion

Open navigation

Coperion

Open navigation